Automatic packers for every need

Within the secondary packaging, SMI offers several solutions that enable to combine the need of an efficient production with that of environmental protection.

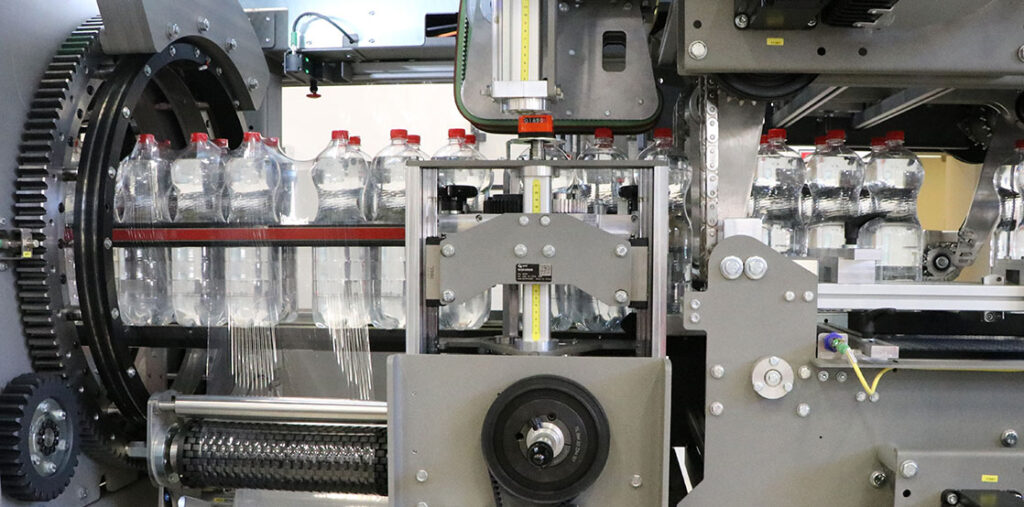

According to the type of product to be packed and to the reference sector, you can choose the most appropriate shrink wrapper among a wide range of automatic shrink wrapping machines for the secondary packaging in stretch film or in recyclable shrink film or among the packers that use corrugated, kraft or Arcwise® cardboard. All automatic packers produced by SMI are inspired by Industry 4.0 and Internet of Things (IoT) principles and ensure cost and energy saving, environmental sustainability and increase in competitiveness.