DEEP FREEZING

TAILOR-MADE SOLUTION

DEEP-FREEZING

TAILOR MADE SOLUTION

Customization,

hygiene and reliability.

Tecnopool’s patented

T-Worth technology ensures greater productivity and increased customer satisfaction of frozen food.

Customization,

hygiene and reliability.

Tecnopool’s patented T-Worth technology ensures greater productivity and increased customer satisfaction of frozen food.

ENERGY SAVINGS

The belt is driven externally by a motor that is smaller in size and consumes less power without affecting the system performance.

HORIZONTAL AIR FLOWS

Cold air flows throughout the spiral, both above and below the product, at a speed of up to 3 m/s guaranteeing an excellent freezing quality.

SEQUENTIAL DEFROSTING

Evaporators can be defrosted individually while the others continue operating. Thanks to this method the system can run 24/7.

EASY TO CLEAN

The absence of a drum-based drive system allows easy access to every part of the freezing system, thus facilitating sanitization.

FAST AND EASY MAINTENANCE

Simpler and faster maintenance, without the need to disassemble parts. Every maintenance operation can be carried out from the outside of the spiral.

FLEXIBLE LAYOUT

Our Spiral Freezer allows infinite configuration options for your processing line. For example freezer infeed and outfeed at the same level.

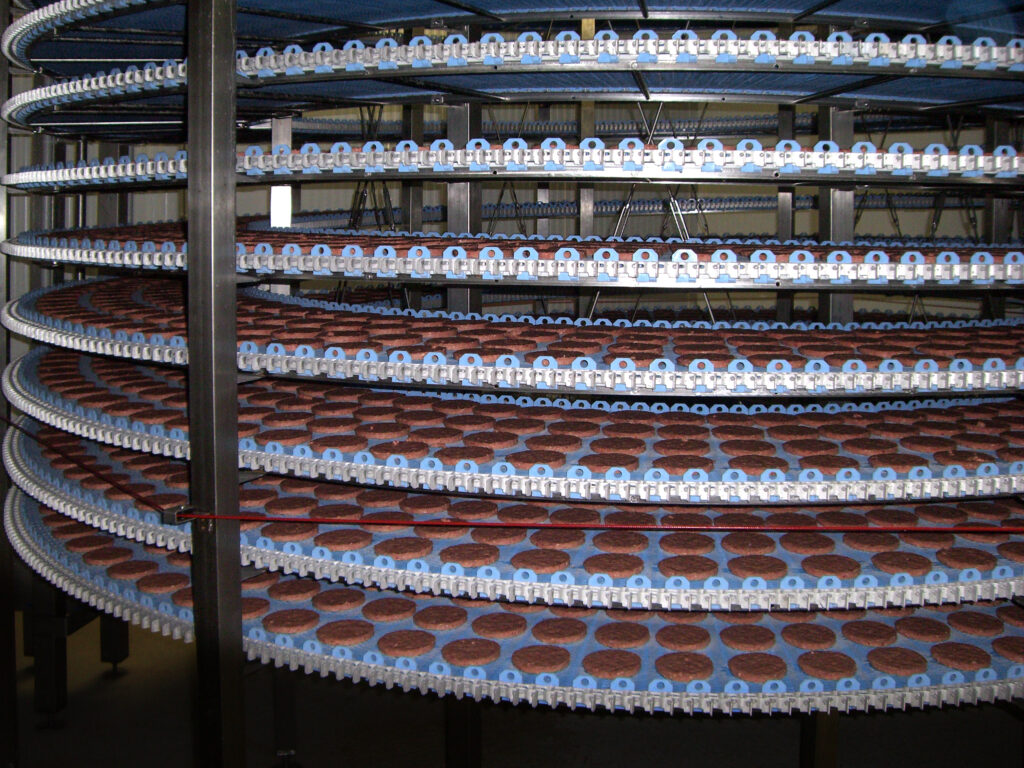

With more than 40 years of food processing experience and specialization, Tecnopool is a standard of reference in Italy and abroad, offering food industry businesses custom installations and complete lines, turnkey basis. Our spiral deep-freezing system with stainless steel T-Worth belt is a unique solution that offers great advantages: from improved product yield, preserving aromas, colors and natural flavors, to maximum design flexibility that makes it possible to place the infeed and outfeed on the same level thanks to a cutting-edge inversion system.

The cabinet consists of prebuilt panels with a thickness ranging from 150 to 200 mm, in which the temperature drops to -40°C. To increase the system’s energy performance and efficiency, the evaporators are sized according to the specifications of the product handled and the needs of each customer. Furthermore, the system can be defrosted without having to interrupt the work cycle, with the use of sequential evaporators.

The spiral, thanks to a central structure without any obstacles and special steel conveyor plates, optimizes the air flow that uniformly processes all the products inside the deep-freezing cabinet, thus improving the quality and yield of the food. This technological solution makes this system extremely easy to clean and fully compliant with food safety hygiene standards. To further reduce cleaning time and costs, the installation is equipped with a clean-in-place system and a belt washing unit.

We welcome Tecnopool customers to come take a look at the solutions we offer in the Test Room, located at our headquarters in San Giorgio in Bosco (PD). In this space, customers can simulate how their products are processed using the company’s installations, including the deep-freezing spiral, and develop bespoke solutions together with our Tecnopool experts and engineers.